Sensor data test platform boosts factory energy efficiency

The test bed allows the efficiency of a factory to be enhanced by reducing energy consumption. The solution is easy to retrofit in virtually any production facility and can increase productivity and improve resource efficiency. The partners developed the test bed within the Industrial Internet Consortium (IIC).

The four partners will present an application for the test bed from the field of plastics processing at this year’s Hanover Fair at the ifm booth (Hall 9, Booth D36). The partners will demonstrate how energy consumption can be reduced through optimum regulation of the air flow for drying material used in the process.

Smart processes require comprehensive information from the sensors. “The necessary data is frequently available via the sensors, but the controllers generally only process a fraction of what is available,” said Dr. Myriam Jahn, managing director, ifm datalink GmbH. With the solution presented at the exhibition, it is now possible to have all sensor data transferred to IT systems without needing to reprogram the controller.

The solution makes it possible to use data in numerous ways such as for condition monitoring, to monitor energy consumption, or to ensure the quality of manufactured products through their seamless traceability. Not only can the efficiency of the processes be improved as a result, but the implementation of energy management processes such as ISO 50001 is also supported at the same time.

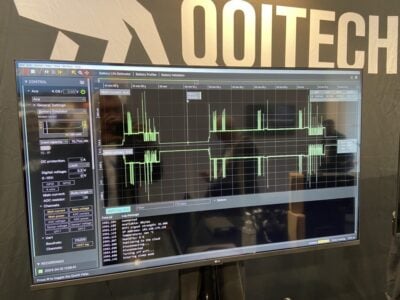

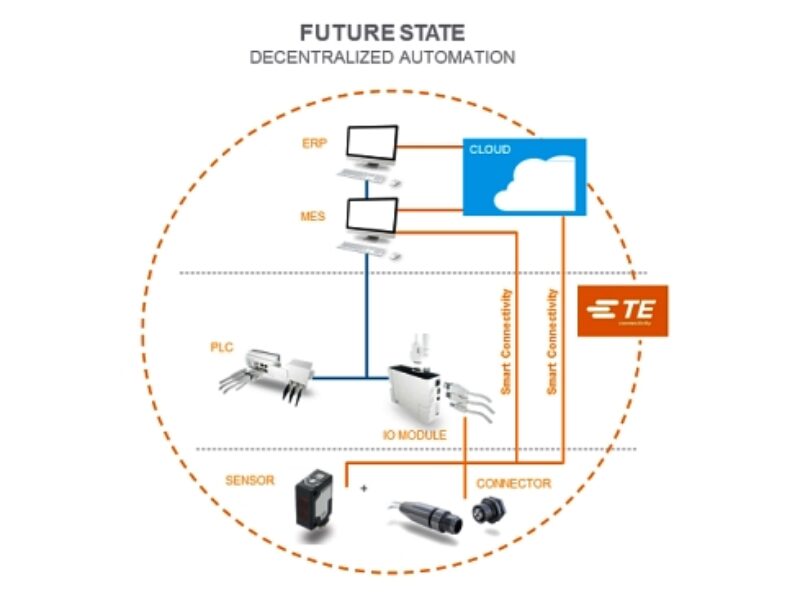

The test platform covers the entire infrastructure required for connecting machine sensors to IT systems. Data communication takes place via IO-Link, OPC UA and Profinet.

“Our contribution lies essentially in using smart connectivity technology to connect various communication protocols and architectures that exist at the different levels to ensure a smooth flow of information from field level to the cloud,” explained Monika Kuklok, senior manager, Innovation Platforms & Ventures at TE Connectivity.

Related articles:

Sensor data predict failure of large machines

Wireless torque sensor features shunt calibration capabilities

Multi-sensor data fusion processing unit targets drones

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News