Magnetic concrete could make wireless EV charging affordable

Magnetizable concrete, advertises Magment founder and CEO Mauricio Esguerra, offers one major advantage over other materials in electrical engineering: it is unbeatable value for money. “Concrete is the most cost-effective material on the market,” says Esguerra. This price advantage applies not only to its manufacture but also to its processing. The magnetizable concrete developed by Magment can be processed in exactly the same way as conventional concrete – the same machines, the same processes. This already reveals an important field of application for this material: automatic charging of electric cars by means of inductors embedded in the road infrastructure. Even charging while driving is possible.

The technology of magnetic concrete is based on the research work of Esguerra and his team at former Siemens Spinoff Epcos. The company developed and produced passive components. Esguerra succeeded in producing a concrete of very homogeneous quality by mixing ferrite particles in cement. “We can control the magnetic parameters very precisely”, says Esguerra.

Magnetizable concrete can be brought into all conceivable forms by pressureless processing. For wireless charging, Magment has developed a kind of tile in which an electrical conductor is embedded. Primary and secondary coils are charged in “a kind of resonance” at 85 kHz. Esguerra says “a kind of resonance”, because the field of resonance charging area is occupied by large companies like Qualcomm; Magment wants to set itself apart from these rivals technically. At a distance of 20 cm, however, his technique can achieve an efficiency of 95%, assures Esguerra.

With its technology, Magment was able to bring on board a yet unnamed Chinese investor. The new partner regards wireless charging as an enabler for autonomous driving with electric cars: If it is possible to charge electric vehicles while they are in operation, these vehicles use much smaller batteries. According to Esguerra, the battery can shrink by up to 80% – with consequences for price and weight of the vehicle. “Instead of a 300 kilowatt battery, you only need 60 kW. This much more compact battery can be installed in a space-saving manner between the wheels.” In addition, charging during operation increases battery life because the battery never reaches extreme low charging states. Currently, the amount of power transferred through wireless charging is limited only by the secondary side – the electronic circuitry inside the vehicles. For the infrastructure side, 200 kW are feasible now, 350 kW are “in sight,” Esguerra says. The velocity of the vehicle has only very little influence on transferrable power and efficiency; Magment tested the technology at speeds of 120 kmph.

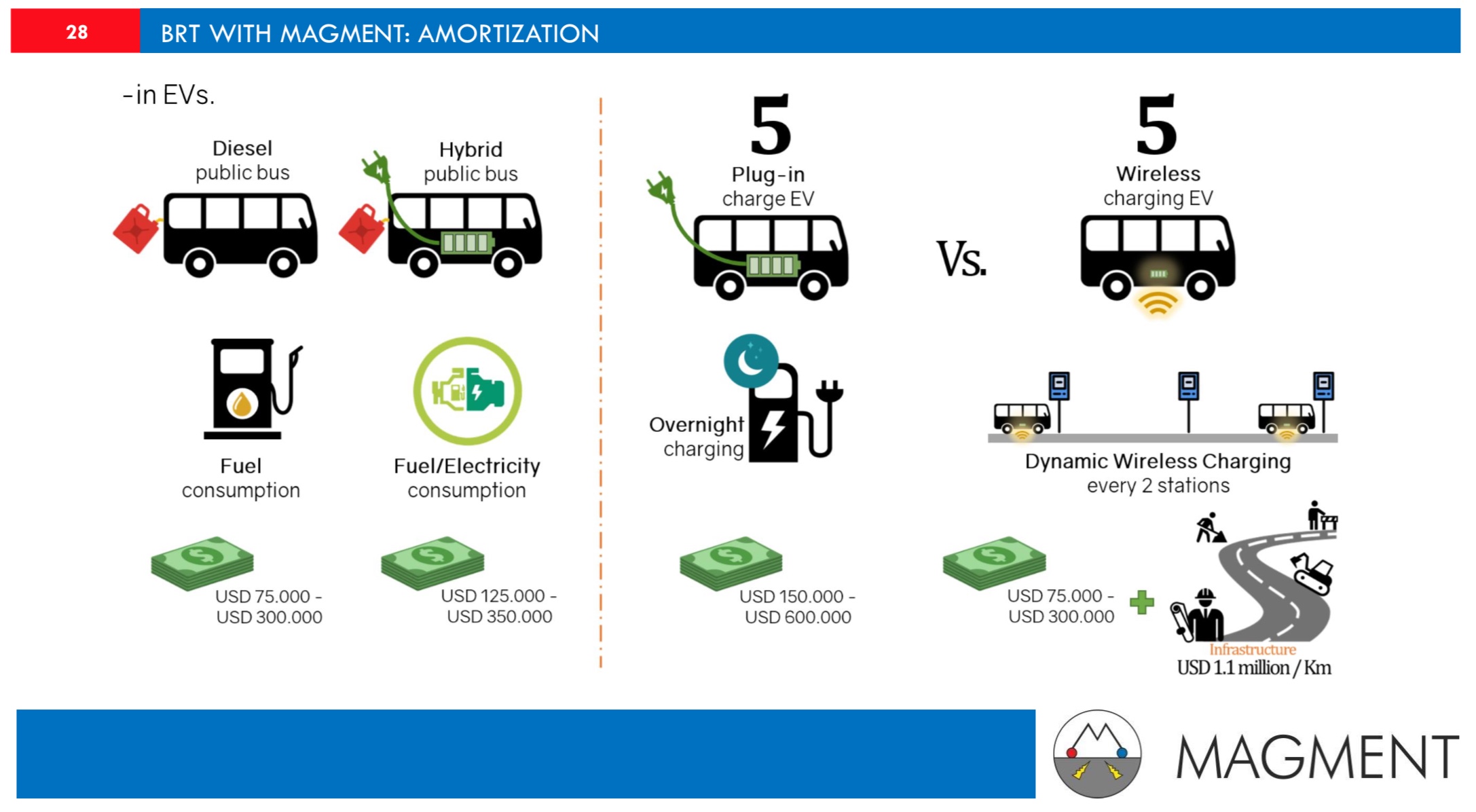

in public transportation, including wireless charging EV

(Source: Magment)

Particularly suitable for “Dynamic Wireless Charging” is public transport in cities and urban agglomerations. The electrification of the bus fleet in many countries often fails due to the cost of vehicles whose comparatively large batteries have to be charged overnight. Due to the smaller batteries, electric buses for wireless dynamic charging could be considerably cheaper. The technology is currently being tested in several research projects in China, Finland and Germany; operating models will also be tested.

Related articles:

Continental automates charging electric cars

Power Magnetics for wireless car charging

Inductive components customized

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News