How 3D printing is disrupting personalized medicine

From its humble beginnings in the late 1980s, through to the global force that it is today, the capabilities of 3D printing technology have expanded dramatically. Conferring advantages such as shorter lead times, reduced waste and opportunity for mass customisation, the potential of 3D printing has gone from strength to strength since. One of the key industries to have successfully leveraged these advantages is the medical and dental industry. In the IDTechEx Research report, 3D Printing in the Medical and Dental Industry 2019 – 2029, 3D printing in the medical and dental industry is forecast to be worth over $8.1 billion by 2029.

3D printing allows the production of a wide range of medical devices such as hearing aids to prosthetic limbs. Use of generative manufacturing printing in these applications leverage its ability for mass customization from 3D imaging data. Personalization is particularly important to medical devices designed to be worn by the patient for extended time, as this improves patient comfort, and with that, adherence to the treatment.

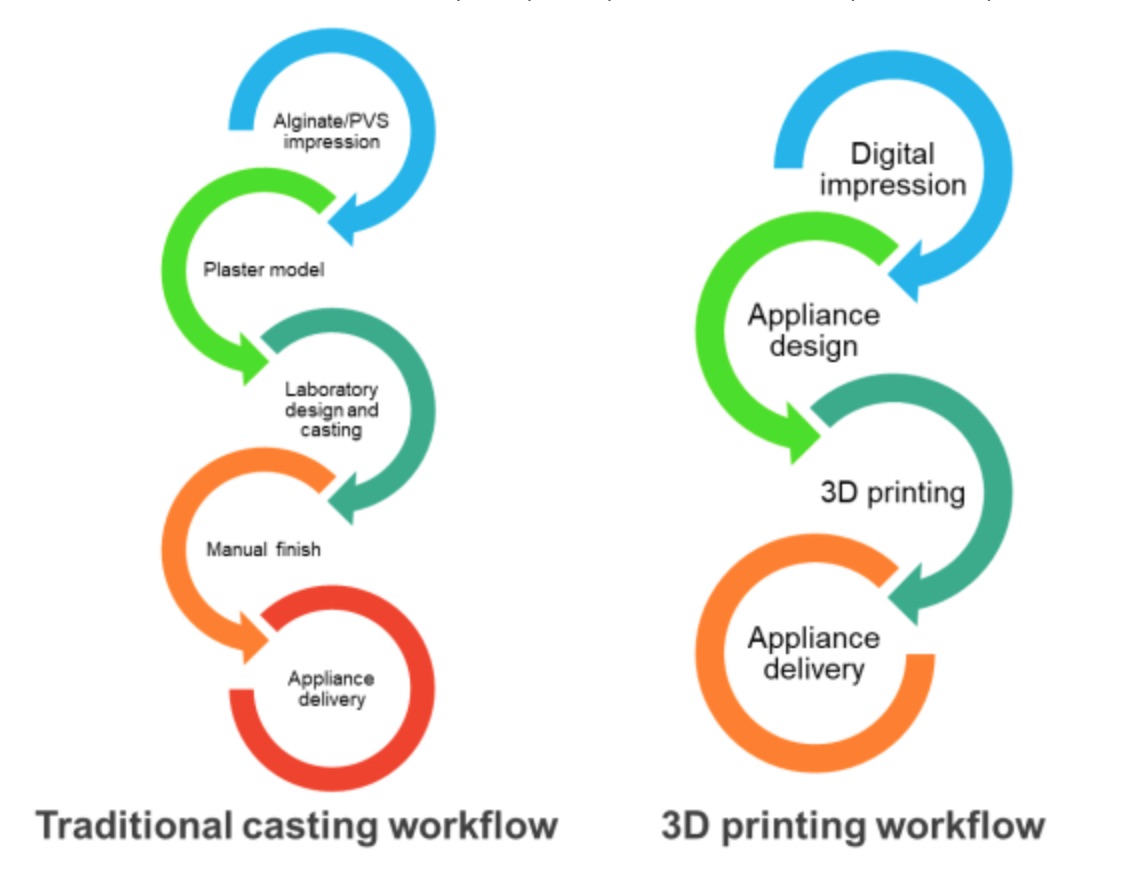

According to IdTechEx Research, no manufacturing process in the medical sector has been as disrupted by 3D printing as that of the hearing aid. 3D printed hearing aids are made with digital precision, an improvement over the lengthy hand-crafting process that sometimes resulted in pieces that were not perfectly fitted and extremely expensive. This is important where less than a millimetre of difference can lead to discomfort for the wearer. Thus, adoption of 3D printing has not only streamlined but also enhanced the manufacturing process.

Given these benefits, 3D printing is gaining popularity in the field of dentistry, and is also emerging as a method of manufacture for several other medical devices where customization is key to improved patient comfort and improved therapeutic outcomes.

the product. Medicine, with its high demand for individual customized

solutions is an ideal applications field.

The range of applications for 3D printing is not limited to the manufacture of medical devices. It is also also used increasingly in surgical procedures. Examples are the creation of patient-specific 3D models for teaching and visualization, intraoperative surgical guides and disposable surgical instrumentation, as well as custom implants, valves, and stents to be implanted into the patient. 3D printing advances surgical standards and improves efficiency, resulting in improved surgical outcomes for the patient. The implants produced this way are durable, lightweight and customized to fit the patient for better functional and aesthetic outcomes, the market researchers say.

Beyond manufacturing medical implants and models, 3D printing can used to create pharmaceuticals, such as patient-specific pills. Personalized medication is especially promising in disrupting the way chronic conditions are treated, by helping patients streamline the number of pills that they must take, and by creating patient-specific dosages that can limit unwanted side effects. As the development of 3D bioprinting continues to evolve, there is even scope for the implantation of personalized organs as part of regenerative medicine.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News