Flexible fuel cell holds promise for wearables, mobile phones

The trick was to design an efficient replacement for these rigid parts. Before they could build their flexible PEMFC, the researchers designed a novel composite electrode by stacking a highly flexible and micro-perforated CNT membrane with carbon paper.

Published their findings in the ACS Nano journal under the title “Flexible and Lightweight Fuel Cell with High Specific Power Density,” the researchers explain how, with their novel design, they were able to remove completely the metal or graphite plates on the cathode side, while replacing the plate on the anode side with a light, flexible and cheap plastic membrane through which they could flow hydrogen. This is because the composite electrode efficiently functioned as the current collector while the light plastic membrane on the anode side operated as the flow field for the hydrogen (fed through a plastic tube).

The paper reports a 1x1cm2 flexible air-breathing PEMFC as light as 0.065 g and as thin as 0.22mm. This new PEMFC exhibits an astounding specific volume and weight power densities as high as 5190W L−1 and 2230W kg−1, several orders of magnitude higher than that of conventional air-breathing PEMFCs and even higher than conventional PEMFCs while being flexible.

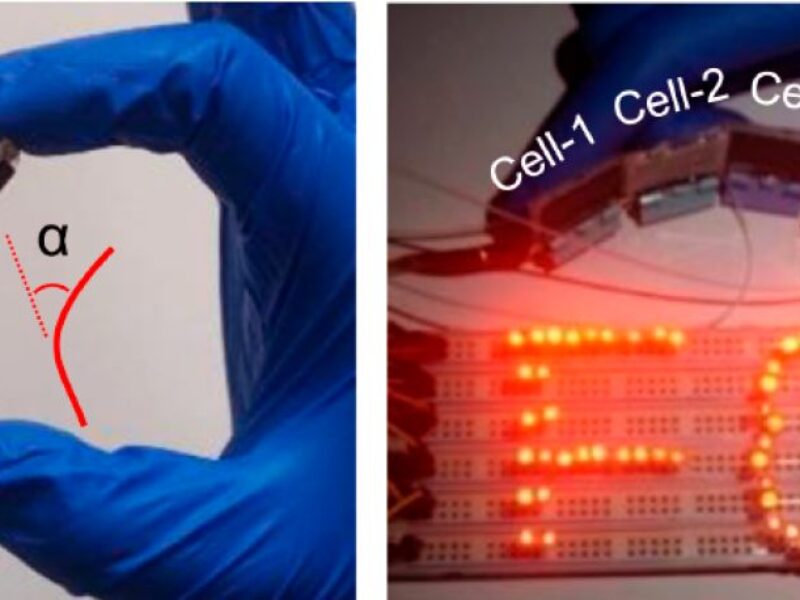

To test the mechanical and power output stability of their novel fuel cell, the researchers built a 4cm long and 1cm wide flexible PEMFC whose output they monitored while subjecting it to hundreds of bending cycles (to 50 degrees).

Upon bending, they noted a negligible current variation of 0.2% of the entire current density (only 0.1mA cm−2 versus 41.4mA cm−2) and the flexible PEMFC recovered its original value when released. Even with a bending angle of around 70°, the current variation was as small as 0.8% of the entire current density. After being bent 600 times at 0.6V, the flexible PEMFC discharge performance only decayed 10.9%.

and on the right side, a flexible air-breathing PEMFC.

Both have a working area of 1x1cm2, but the flexible

implementation is thinner and has a specific weight

power density several orders of magnitude higher than

that of the conventional air-breathing PEMFC.

Because these flexible PEMFCs are also much easier to mass produce than traditional PEMFCs, the researchers expect those could be stacked to power wearable applications as well as mobile phones. In the race of all things flexible, these cheap PEMFCs could displace tentative flexible lithium battery designs or even flexible supercapacitors, for which they quote specific weight power densities of 180 and 40Wh kg−1 from literature.

Suzhou Institute of Nano-Tech and Nano-Bionics – www.mscatalysis.net

Related articles:

Stretchable zinc battery promises self-powered wearables

Molex to manufacture printable flexible battery

Thin and flexible energy harvesting could be cheap

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News