Artificial eye can simultaneously control focus, astigmatism, and image shift

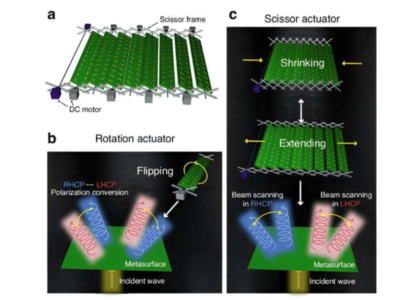

To create the artificial eye, the researchers combined a metalens – a lens made from an engineered material not found in nature – and artificial muscle technology. The result is an adaptive, tunable metalens that can change its focus in real time – just like the human eye, say the researchers.

However, says Alan She, an SEAS graduate student at the Graduate School of Arts and Sciences, and first author of a paper on the research, “We go one step further to build the capability of dynamically correcting for aberrations such as astigmatism and image shift, which the human eye cannot naturally do.” The resulting adaptive metalens can simultaneously control for three of the major contributors to blurry images: focus, astigmatism, and image shift.

This, say the researchers, demonstrates the feasibility of embedded optical zoom and autofocus for a wide range of applications, including cell phone cameras, eyeglasses, and virtual and augmented reality hardware. In addition it shows the possibility of future optical microscopes that fully operate electronically, and compact optical systems that use the principles of adaptive optics to correct many orders of aberrations simultaneously.

Metalenses focus light and eliminate spherical aberrations through a dense pattern of nanostructures, each smaller than a wavelength of light. Earlier metalenses were about the size of a single piece of glitter, and to create their adaptive metalens, the researchers needed to find a way to scale up the metalens.

“Because the nanostructures are so small, the density of information in each lens is incredibly high,” says She. “If you go from a 100 micron-size lens to a centimeter-size lens, you will have increased the information required to describe the lens by 10,000. Whenever we tried to scale up the lens, the file size of the design alone would balloon up to gigabytes or even terabytes.”

Ultimately the researchers developed a new algorithm to shrink the file size to make the metalens compatible with the technology currently used to fabricate integrated circuits. They were then able to demonstrate the design and fabrication of metalenses of up to centimeters or more in diameter.

“This research provides the possibility of unifying two industries, semiconductor manufacturing and lens-making,” says Federico Capasso, the Robert L. Wallace Professor of Applied Physics and Vinton Hayes Senior Research Fellow in Electrical Engineering at SEAS and senior author of the paper on the metalens, “Whereby the same technology used to make computer chips will be used to make metasurface-based optical components, such as lenses.”

The researchers then needed to adhere the large metalens to a dielectric elastomer actuator – also known as an artificial muscle – without at the same time compromising its ability to focus light. They used a thin, transparent dielectic elastomer with low loss — meaning light travels through the material with little scattering — to attach to the lens, and developed a platform to transfer and adhere the lens to the soft surface. Together, the lens and elastomer “muscle” are only 30 microns thick.

The elastomer is controlled by applying voltage. As it stretches, the position of pillar shaped nanostructures (nanopillars) on the surface of the lens shift. The metalens can be tuned by controlling both the position of the pillars in relation to their neighbors and the total displacement of the structures.

“All optical systems with multiple components — from cameras to microscopes and telescopes — have slight misalignments or mechanical stresses on their components, depending on the way they were built and their current environment, that will always cause small amounts of astigmatism and other aberrations, which could be corrected by an adaptive optical element,” says She. “Because the adaptive metalens is flat, you can correct those aberrations and integrate different optical capabilities onto a single plane of control.”

Looking ahead, the researchers next plan to further improve the functionality of the lens and decrease the voltage required to control it. For more, see “Adaptive metalenses with simultaneous electrical control of focal length, astigmatism, and shift.”

Related articles:

Broadband metalens opens new possibilities in virtual, augmented reality

Lensless ‘camera of the future’ opens new imager applications

Lens-free flat camera addresses emerging imaging applications

Microsoft curved image sensor promises ‘ideal’ camera

Flexible tactile actuator holds promise for wearable haptics

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News