3D printing system produces plastic parts 8 times faster

With today’s additive manufacturing technologies, It can take up to an hour to produce a component from molten plastic. This process is far too slow to produce components in large series, such as those required by the automotive industry. The SEAM (Screw Extrusion Additive Manufacturing) system, developed by the Fraunhofer Institute for Machine Tools and Forming Technology (IWU) in Chemnitz, Germany, now raises 3D printing speed to a new level: Their high-speed technology takes just 18 minutes to produce a 30-centimeter-long plastic component. A research team at Fraunhofer IWU has developed it for the additive production of large-volume, sturdy plastic components. Tool manufacturers, as well as the automotive and aviation industries, benefit from the fast 3D printer, which increases process speed by a factor of 8.

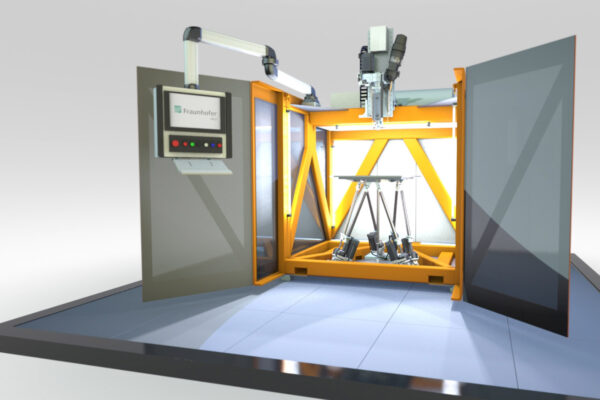

The researchers achieved the high process speed of the SEAM process by combining machine tool technology with 3D printing, explains Fraunhofer scientist Dr. Martin Kausch. To process the plastic, the researchers use a specially designed unit that melts the raw material and ejects it at a high output rate. They installed this unit above a construction platform that can be swivelled on six axes with the help of a machine tool’s motion system. “This combination is unique to date,” says Dr. Kausch. The hot plastic is applied to the construction platform in layers.

The machine’s motion system ensures that the construction panel slides along under the nozzle in such a way that the previously programmed component shape is produced. The table can be moved at a speed of one meter per second in the X, Y and Z axes and tilted by up to 45 degrees.

in less than 20 minutes, making 3D printing suitable for series production

Every hour, up to seven kilograms of plastic are pressed through the hot nozzle with a diameter of one millimeter. The comparable 3D printing processes FDM (Fused Deposition Modeling) or FLM (Fused Filament Modeling) usually achieve only 50 grams of plastic per hour. The special feature: instead of expensive FLM filament, SEAM processes free-flowing, low-priced standard plastic granulate into sturdy, fiber-reinforced components several meters in size. In this way, material costs can be reduced by a factor of 200.

With SEAM, complex geometries can be realized without support structures. With the new system, it is even possible to print on existing injection molded components. “Since our construction platform can be swivelled, we are able to print on curved structures with a separately moved Z-axis,” says Kausch. “We were able to process a wide variety of plastics in tests. This ranges from thermoplastic elastomers to high-performance plastics with 40 percent carbon fiber. These are materials that are particularly relevant to industry and that cannot be processed with conventional 3D printers.”

This innovative technology will be presented for the first time at the Hannover Messe 2019. From April 1 to 5, researchers from the Fraunhofer IWU will be presenting their ultra-fast 3D printer during operation (Hall 2, Stand C22).

More information: https://www.iwu.fraunhofer.de/en.html

Related articles:

3D-printed RF amp marks additive manufacturing ‘breakthrough’

How 3D printing is disrupting personalized medicine

Evaluation methodology for 3D printing allows greater design variety

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News