Optical mic ‘hears’ wider sound spectrum

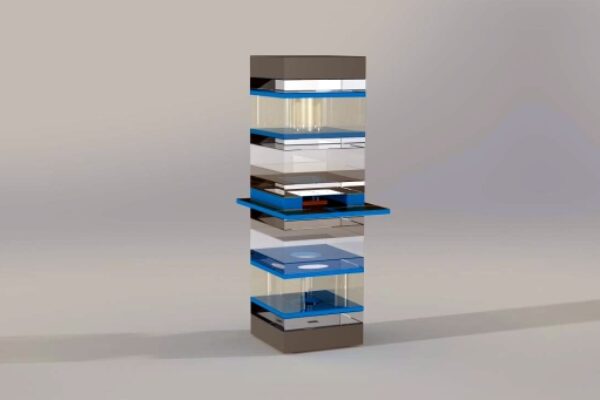

Sending a telecom-grade 1550-nm IR laser beam through an open Fabry-Pérot etalon (in effect two parallel optical mirrors only 2 mm apart, the solid-state microphone (no moving parts) records sound pressures as minute changes in the medium’s refractive index. These changes alter the optical wavelength and the light transmission which the optical microphone converts into measurable electrical signals.

microphone’s working principle.

Xarion’s optical microphone can detect faint refractive index changes under 10-14, which translate to pressure changes as small as 1 µPa. Due to their rigid construction, they do not suffer from sound-induced mechanical resonances and boast a very flat frequency response, from 5-Hz infrasound to ultrasounds in the megahertz range (up to 25 MHz in liquids). This enables the optical microphone to capture all acoustic data in one recording across a large spectrum otherwise unattainable by conventional membrane-based microphones.

For now, Xarion’s prototypes could be considered fairly bulky compared to today’s MEMS-based consumer microphones found in smartphones, and eeNews Europe caught up with the company’s CEO, Dr. Balthasar Fischer, to better understand which markets the startup is after.

“Of course, why would you want to record sounds that only bats can hear?” jokingly admitted Fischer with regard to audiophile applications. “The frequencies we can record make more sense for industrial applications such as non-destructive testing, ultrasound metrology, acoustic process monitoring or for medical imaging”.

“Also, as a startup, we would not be able to address mass-markets, our current devices would not be cost competitive with consumer-grade products so it makes sense for us to start with niche markets” Fischer said.

“For non-destructive testing, we can operate one-sided, with a sound emitter on the side of the microphone. By scanning a surface across a 2D plane, we can identify internal structural defaults which yield different sound patterns” the CEO explained.

composite plate exhibiting internal defects

(source: Technical University of Munich)

drilling bits in the ultrasound range.

“For process control, we can monitor high-speed CNC machinery in the ultrasound regime way beyond ambient noise, which gives us a richer picture because we can focus on the signal emitted by the tool” he said, “as if you were only listening to the tools in an otherwise silent room”.

Another example Fischer wrote about in a recent paper is laser welding, where the amplitude of specific spectral components in the hundreds of kilohertz is strongly tied to the weld’s depth of penetration, a key measure of weld quality.

“In cooperation with the Medical University of Vienna, our optical microphone is also being evaluated for endoscopy, designing photoacoustic imaging solutions for surgery. But it can also be used in dermatology, to analyse the structure of the skin very much in the same way as you would for non-destructive testing. We can get very sharp 3D images of dark moles” the CEO revealed.

(a black print on a 1-inch piece of glass) discerned by the

optical microphone through an ultrasound scan.

After addressing these three markets, the startup aims to enter the consumer market via the automotive industry.

“Because our optical microphone has a very good phase response, it is better suited to directional sound recording than traditional microphones. Using an array of three to seven microphones we could use beam-forming algorithms to listen into one spatial direction, say for better voice recognition. We could listen to a well-known spot and avoid 360º surrounding noises” Fischer said, hinting at a driver’s head position in a noisy car interior.

“Since 2014, Mr Porsche is our largest shareholder”, he added, confident that such an application could interest car makers in the next few years when the technology matures.

For now, the company aims to ship between hundreds and thousands of pieces a year for industrial applications and is working with partners in the medical sector to go through regulatory approvals.

“We are still pre-break even, but we have customers and we are generating some revenues. We just need to follow up with our product development. Though we are not currently looking for more financing because we already have very good backers.”

The CEO knows well further miniaturization and cost-reductions will be necessary to ramp up production and address consumer applications.

“We are currently developing wafer-level glass interferometers, with integrated VCSELs. The optical cavity here would be 1 mm instead of 2 mm, we could have thousands of interferometers per wafer. Of course, it would still be larger than MEMS microphones and we would not beat MEMS for pricing, but the comfort these microphones would bring to car drivers when they speak to their navigational system would make up for it.”

Design parameters could be further tweaked, playing with cavity length, mirror reflectivity or even changing the laser wavelength.

“You could choose to use the UV band for more sensitivity or to listen into a medium where infrared would be too much absorbed” said Fischer, adding that he had received a few requests for such a development. “For a military application, we diminished the reflectivity of the mirrors so we would decrease the sensitivity, to listen at very high sound pressure levels. At 180 dB, we had to put on double hear protections” he cited as another example.

Visit Xarion Laser Acoustics GmbH at www.xarion.com

Related articles:

Graphene condenser mic outperforms commercial units

Smart MEMS microphone market emerges

Graphene outperforms other materials at high frequencies, says study

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News