Battery researcher: A range of 1000 km is possible

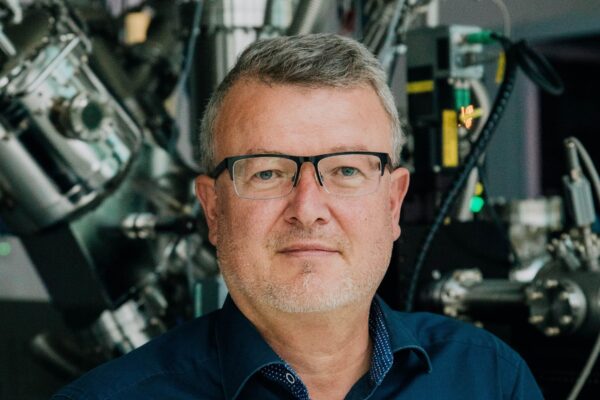

Traction batteries will make great strides in two particular areas over the next few years, believes Maximilian Fichtner, Head of Energy Storage Systems at the Karlsruhe Institute of Technology. These areas are, on the one hand, the storage materials and, on the other hand, the construction of the batteries.

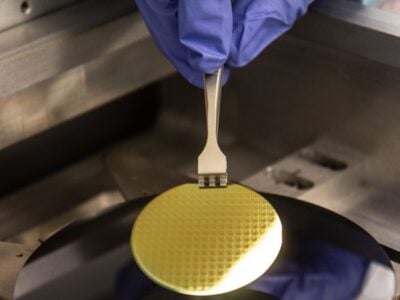

In the field of battery materials, the anode side in particular gives cause for hope: according to the scholar, a composite of graphite and silicon could soon replace the currently predominant pure graphite. Silicon has a ten times higher storage density than graphite, which would significantly increase the energy content of the batteries. Fichtner expects advantages in the construction of the batteries from new construction techniques, with which considerably more storage material could be accommodated in the same form factor. “With today’s construction, the actual active storage materials only occupy 25 to 30 per cent of the battery volume. The rest is accounted for by the housing, packaging and additives,” Fichtner describes the problem – and the potential solution: “Future battery systems will use the installation space more efficiently, the proportion of storage material could almost double,” the expert says. The new design approaches would simultaneously increase the energy content and reduce costs.

Fichtner sees another approach in the development of solid-state batteries. These offer the possibility of replacing the graphite at the negative pole with metallic lithium. That would increase the range by a leap of 30 to 40 per cent. “That is the reason why the solid-state battery is considered the holy grail of battery research,” says Fichtner. However, there are still uncertainties in this field of research because this type of battery is not yet available in industrial form and the costs cannot yet be clearly stated either.

The degree of industrialisation of today’s lithium-ion batteries is already so advanced that a falling cost curve can be clearly foreseen. The introduction of lithium iron phosphate as a cathode material has already made it possible to fall below the important mark of 100 dollars per kilowatt hour. “That is the magic threshold below which an electric car becomes cheaper than a combustion engine,” says Fichtner.

Based on all these improvements that have been realised or are within reach, the KIT expert assumes that electric ranges of significantly more than 500 km will soon be a matter of course. “Even 1000 km range is quite possible,” Fichtner promises.

However, even with the improvement of the batteries, Fichtner believes that all the lights are not yet green for electric cars: in order to finally convince consumers of this type of drive, the charging infrastructure would still have to be significantly expanded (Fichtner’s comments refer to Germany, but it can be assumed that the problem is similar in many European countries). Above all, according to Fichtner, the nationwide provision of high-performance fast charging stations is necessary. In addition, a lot needs to be done so that city dwellers without their own wallboxes can charge their e-cars easily and conveniently. Last but not least, a clear and uniform pricing structure for charging is necessary.

Related articles:

€5m for production of sodium battery cells for electric cars

Fisker throws in the towel on solid-state battery development

QuantumScape sets up solid state battery pilot line

Can hydrogen be cheaper than oil?

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News