Wearable thermoelectric generators move closer to reality

The researchers used conducting polymers in symmetrical fractal wiring patterns to cut the size of the generators needed to provide the voltage and power requirements for specific applications. The modular generators could be inkjet printed on flexible substrates, including fabric, and manufactured using inexpensive roll-to-roll techniques.

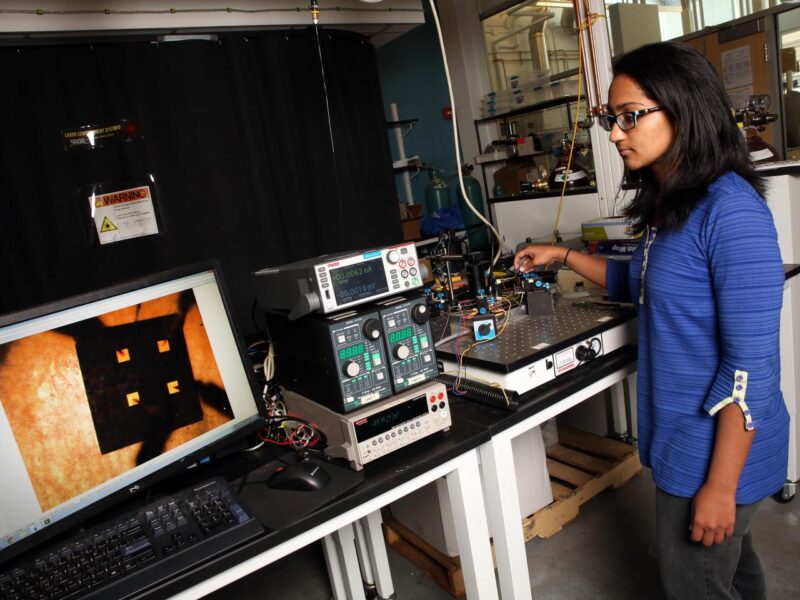

“The attraction of thermoelectric generators is that there is heat all around us,” said Akanksha Menon, a researcher in the Woodruff School of Mechanical Engineering at the Georgia Tech (above). “If we can harness a little bit of that heat and turn it into electricity inexpensively, there is great value. We are working on how to produce electricity with heat from the body.”

The team in the laboratory of Assistant Professor Shannon Yee designed a device with thousands of dots composed of alternating p-type and n-type polymers in a closely-packed layout. Their pattern converts more heat per unit area due to large packing densities enabled by inkjet printers. By placing the polymer dots closer together, the interconnect length decreases, which in turn lowers the total resistance and results in a higher power output from the device.

“Instead of connecting the polymer dots with a traditional serpentine wiring pattern, we are using wiring patterns based on space filling curves, such as the Hilbert pattern – a continuous space-filling curve,” said Kiarash Gordiz, a fellow researcher.

The researchers use commercially-available p-type materials, and are working with chemists at Georgia Tech to develop better n-type polymers for future generations of devices that can operate with small temperature differentials at room temperatures.

“One future benefit of this class of polymer material is the potential for a low-cost and abundant thermoelectric material that would have an inherently low thermal conductivity,” said Yee, who directs the lab. “The organic electronics community has made tremendous advances in understanding electronic and optical properties of polymer-based materials. We are building upon that knowledge to understand thermal and thermoelectric transport in these polymers to enable new device functionality.”

Among the other prospects for the materials being developed are localized cooling devices that reverse the process, using electricity to move thermal energy from one side of a device to another. Cooling just parts of the body could provide the perception of comfort without the cost of large-space air conditioning, said Yee.

The new circuit design also has another benefit: its fractally symmetric design allows the modules to be cut along boundaries between symmetric areas to provide exactly the voltage and power needed for a specific application. That eliminates the need for power converters that add complexity and take power away from the system.

“This is valuable in the context of wearables, where you want as few components as possible,” said Menon. “We think this could be a really interesting way to expand the use of thermoelectrics for wearable devices.”

So far, the devices have been printed on ordinary paper, but the researchers have begun exploring the use of fabrics. Both paper and fabric are flexible, but the fabric could be easily integrated into clothing. “We want to integrate our device into the commercial textiles that people wear every day,” said Menon. “People would feel comfortable wearing these fabrics, but they would be able to power something with just the heat from their bodies.”

The researchers expect to get enough electricity to power small sensors, in the range of microwatts to milliwatts. That would be enough for simple heart rate sensors and could also supplement batteries. Among the challenges ahead are protecting the generators from moisture and determining just how close they should be to the skin to transfer thermal energy – while remaining comfortable for wearers.

The research is also supported by the US Air Force Office of Scientific Research and was reported online in the Journal of Applied Physics.

Related articles:

FLEXIBLE PRINTED BATTERY CAN POWER WEARABLE SENSORS

HARNESSING ELECTRICITY FROM BLOOD FLOW

GERMAN RESEARCHERS SHOW KINETIC ENERGY HARVESTING SYSTEMS FOR WEARABLES

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News